RITHCO®ret MPA

Dewatering aids for paper and board manufacturing

General

RITHCO®ret MPA is an anionic sodium silicate and part of the RITHCO System for improving retention, drainage and dewatering in paper and board production.

RITHCO®ret-MPA has strong anionic activity which reacts with cationic flocs created by other polymers such as RITHCO®ret and with fibers, fines and fillers that have cationic charge.

The ultra-fine particle size of RITHCO®ret-MPA allows the neutralization of surcharge of cationic load in otherwise hidden locations on and in fibers.

By neutralization of electrostatic repulsion and release of bound water there is a strong linking together of polymer loaded fibers, fines and fillers to form a very fine and stable floc.

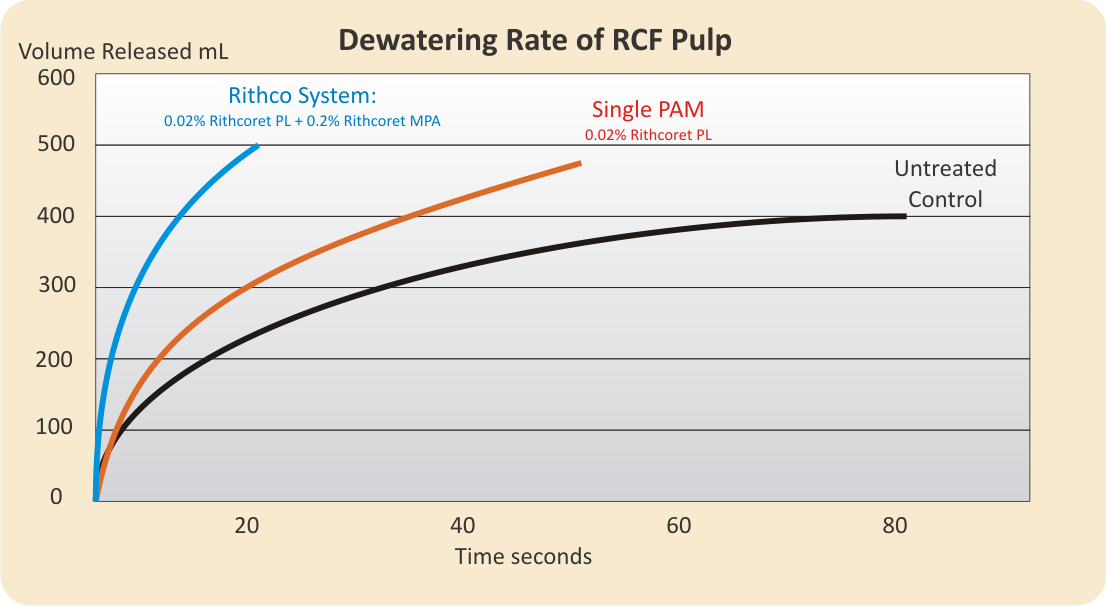

RITHCO®ret-MPA has the ability to give good formation while at the same time generate good retention, fast dewatering and higher tensile strength of the paper by higher retention of starch.

Retention in heavily loaded systems can be improved by using cationic fixing agents or trash removers, such as RITHCO®fix.

Use and application

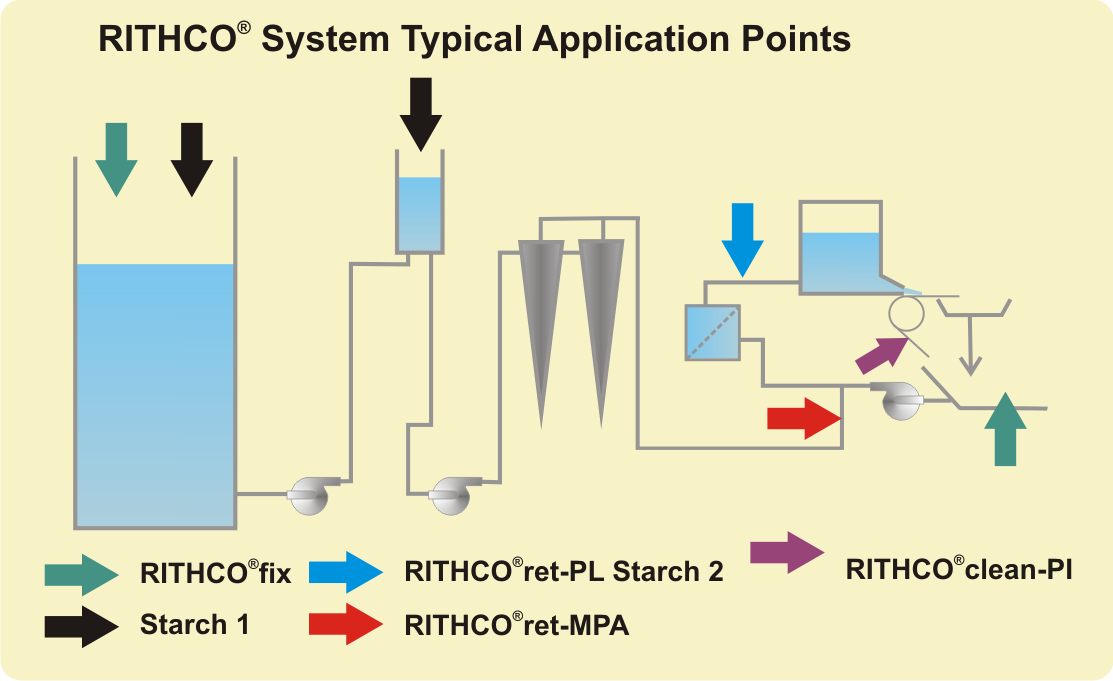

RITHCO®ret-MPA products are applied in the wet-end of paper and board machine as part of a total retention system.

They can be applied in fine papers, LWC, printing and writing papers, as well as in certain areas of board manufacturing, specially where recycled paper is used. In most cases it is applied together with other components such as retention aids, fixing agents, cationic or highly cationic starch.

The system is highly recommended for retention and drainage systems in neutral or alkaline paper making.

Advantages of RITHCO®ret MPA

esults with RITHCO®ret MPA

Improvements of drainage with the use of RITHCO®ret MPA can benefit the operation by:

- Improved runnability by drier sheet at potential breaking locations on the machine

- Better formation by lower flow-box consistency

- Lower drying costs by higher sheet solids

For certain pulp systems and for specific situations additional components besides RITHCO®ret-MPA might be necessary.

Food Contact Regulations

RITHCO®ret-MPA products comply with the German regulation, outlined in the latest version of recommendation XXXVI (Paper and board for food wrapping) of the BfR (Bundesinstitut für Risikobewertung).