The RV-System – Deinking

Fiber cleaning to a new level

Introduction

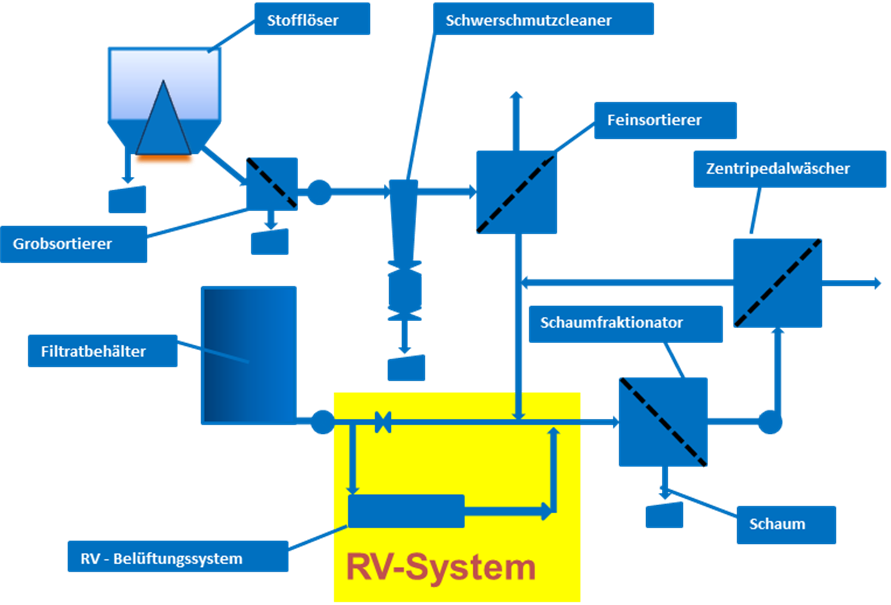

The ability of the Airjec® to generate a massive bubble flow has been used as pre-aeration of stock ahead of a separation stage such as a flotation stage.

The RV-System® technology provides a new concept in stock cleaning – soft friction between the feed-stock materials and fast moving air / water mixture – which very effectively separates fibers from contaminants. The air is then used to float off the unwanted material.

RV-System Principle

The system is based on three stages:

- A unique aeration system, the Airjec®

- A specific reaction chamber to “soft rub” the contaminants from the fibers and attach them to micro-bubbles

- A flotation separation stage

RV-System Velocity

The resulting velocity of 4-5 m/s (12-16 ft/sec), with the shape of the chamber, generates the high, soft friction that separates the impurities (fillers, ashes, pigments, colors and stickies) from the fibers. These then adhere to the air bubbles. At this stage bubbles are present in a wide range of sizes, from micro to macro aiding collection of contaminants of all types.

The mixture is quickly passed on to the flotation stage for separation of the contaminants.

RV-System is designed to remove most of the impurities from the fibers before the paper, tissue or paperboard machine so no recycling of fine contaminants occurs in the water circuit.

This is achieved at low energy and operational costs.